LANG Technik GmbH

หมายเลขบูธ: AS14

www.lang-technik.de

เกี่ยวกับเรา

LANG Technik is a worldwide leading company in the field of workholding and automation technology. The main product focus is on zero-point and workpiece clamping as well as machine tool automation. With state-of-the-art and mainly patented solutions, LANG Technik helps machining companies to simplify production processes, to manufacture more efficiently and to make ideal use of production resources. Customers of all sizes from a wide range of industries rely on the innovative strength of LANG Technik and its 40 years of experience in the machining industry.

ที่อยู่

Albstr. 1 - 6

73271 Holzmaden

Germany

อีเมล: info@lang-technik.de

โทรศัพท์: +49 7023 9585-0

อินเทอร์เน็ต: www.lang-technik.de

เลขที่ 5 ซอยสวนสยาม 6 แยก 2 ถ.สวนสยาม แขวงคันนายาว

10230 เขตคันนายาว กรุงเทพฯ

Thailand

อีเมล: surapong@solutionss.co.th

โทรศัพท์: +66 2919 7176

ผู้ติดต่อ:

Tobias Farr

อีเมล: t.farr@lang-technik.de

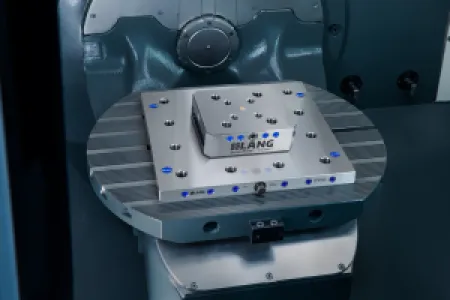

Quick-Point 0-Point System

The Quick•Point® zero point clamping system is characterized by a particularly wide range of variants and offers a suitable solution for every machine tool. Whether round, rectangular or square in shape, for single or multiple clamping, it can be used universally in vertical and horizontal machining centers, on 3- / 5-axis tables or rotary tables. The simple mechanical operation, solid construction, high precision, and enormous set-up time savings make the Quick•Point® zero point clamping system one of the best on the market.

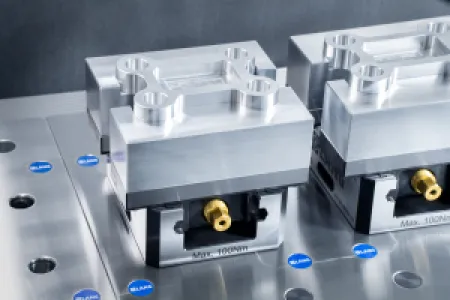

Makro-Grip 5-Axis Vice

The Makro•Grip® 5-axis vise is the perfect clamping device for 5-sided machining of raw parts. Thanks to its compact design and the low clamping depth of the workpieces, it offers particularly good accessibility and at the same time enables high material savings. Thanks to its form-fit clamping technology, the Makro•Grip® offers the highest holding forces and therefore maximum safety. Despite great holding forces, only low clamping forces are required, which enables distortion-free, secure, and gentle clamping. This has a positive effect on the workpiece quality and the durability of the clamping device.

Clean-Tec Chip Fan

The Clean•Tec chip fan cleans the inside of the machine and removes chips and coolant without the operator needing to open the machine door. It thus enables automatic in-process cleaning of workpieces and fixtures after the machining process. It is called up via the machine program and exchanged from the tool magazine just like a regular tool. The Clean•Tec opens and closes its blades by controlling the speed of the machine spindle. It is an indispensable tool, particularly in automated production. Before the automatic removal, it cleans all critical interfaces between the clamping

RoboTrex Automation

RoboTrex is an automation system that can be connected and retrofitted to almost any machine tool. Utilizing automation trolleys as a storage medium for vises, as opposed to pallets, the vises are removed directly by a Fanuc robot and fed to the machine tool. RoboTrex covers all requirements, from single part production to large series. It is versatile, easy to operate and offers an excellent cost-benefit ratio. In addition to a high storage capacity on a small footprint, RoboTrex is particularly impressive due to its set-up time savings when loading and unloading the automation system.