ultraTEC innovation GmbH

Booth number: AT13

ultratec-anlagen.de/en

About us

ultraTEC innovation GmbH from Leupheim, a subsidiary of the Vollmer Group, has developed a new and unique process for the automated, contactless deburring of components.

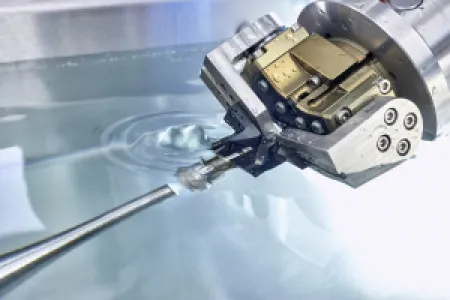

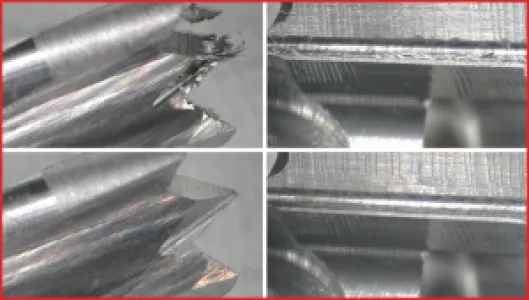

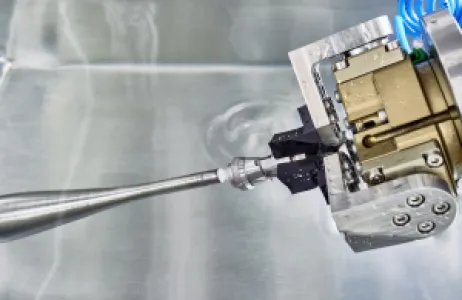

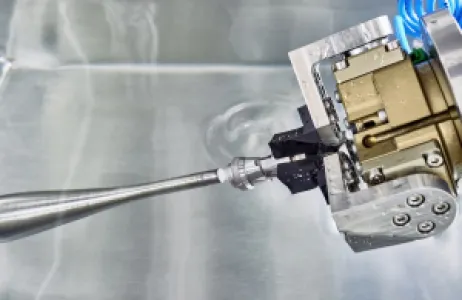

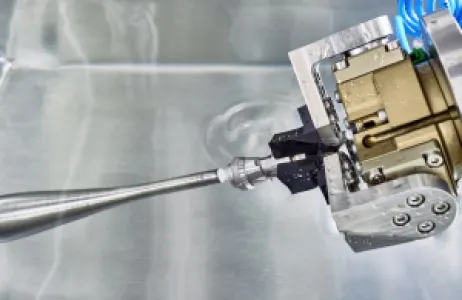

Every machining process produces burrs and protruding fibers that are often difficult to remove with conventional methods. ultraTEC’s innovative systems use the power of ultrasound: Workpieces are guided through a process water bath at the tip of a sonotrode, whose vibrations remove burrs and fibers precisely and energy-efficiently—while protecting the component surface.

This cutting-edge process combines highest precision with efficiency and sustainability. The company relies on advanced technology and close collaboration with customers to optimize manufacturing processes and significantly enhance component quality.

Address

Uhlmannstr. 46

88471 Laupheim

Germany

E-mail: sales@ultratec-innovation.de

Phone: +49 7392 9286266

Internet: ultratec-anlagen.de/en

No.68 Moo 9, Soi Bearing 12, Sukhumvit 107 Road

Samrong Nuea, Mueang

10270 Samut Prakan

Thailand

E-mail: info-voap@vollmer-group.com

Phone: +66 23941068

Internet: www.vollmer-group.com/en/

Contact person:

Andreas Weidenauer

Managing Director Vollmer Asia Pacific Co. Ltd.

E-mail: a.weidenauer@vollmer-group.com

Products & Services

Experience the revolution in deburring: Optimal results without material removal and with minimal energy consumption – ultrasonic deburring redefines precision! A new process that eliminates the drawbacks of previous alternatives.

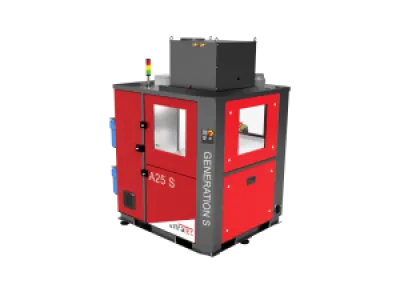

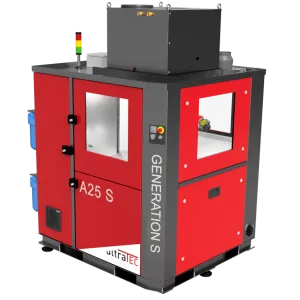

A25 S

Our flexible system for complex components.

For complex components up to a max. component weight of 7kg and a max. component size of approx. 150x150x150 mm.

Two or optionally three sonotrodes installed in the process water basin enable the processing of complex components with different sonotrodes in one set-up. By arranging the sonotrodes at different angles, the A25 S impresses with its high degree of flexibility. The system enables unmanned production with up to 6 automatic drawers (optional)

A20 C

Our compact machine.

For complex components up to a max. component weight of 1.5kg and a max. component size of approx. 100x100x100 mm.

Two sonotrodes installed against each other in the process water basin enable the processing of complex components with different sonotrodes in one clamping.

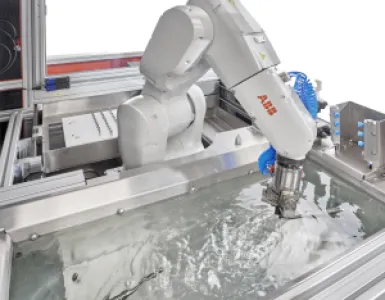

The machine impresses with its compact design and comes with 2 drawers for automated component feeding. A 6-axis industrial robot for component handling stands on a welded steel machine bed, which is partially filled with mineral concrete. This gives the machine maximum stability. The housing is made of high-quality aluminium profiles.

A100 S

Our flexible system for large components.

For complex components up to a max. component weight of 11kg and a max. component size of approx. 300x300x300 mm.

Two or optionally three sonotrodes installed in the process water basin enable the processing of complex components with different sonotrodes in one clamping. By arranging the sonotrodes at different angles, the A100 S impresses with its high degree of flexibility. The system enables unmanned production with up to 6 automatic drawers (optional).

A 6-axis industrial robot for component handling stands on a welded steel machine bed, which is partially filled with mineral concrete. This gives the machine maximum stability. The housing consists of a welded steel housing.