GW ADVANCE ENGINEERING CO.,LTD.

Booth number: AS09

www.gwadvance.co.th/

About us

GW Advance Engineering is robotic automation integrators with a team of highly experienced professionals to provide machine and equipment for industrial automation to our customers with quality products and solutions as well as collaboration with our customers and suppliers to deliver the technical expertise for productivity improvement and Educational Technology.

Address

5/21 Vizio Rom Klao - Suvarnabhumi,Rom Klao Rd., Khlong Sam Prawet, Lat Krabang

10510 Bangkok

Thailand

E-mail: krissanai@gwadvance.co.th

Phone: +66 81 5622703

Internet: www.gwadvance.co.th/

vizio Rom Klao - Suvarnabhumi,Rom Klao Rd.

Khlong Sam Prawet,

10520 Lat Krabang

Thailand

E-mail: krissanai@gwadvance.co.th

Phone: +66 81 5622703

Internet: www.gwadvance.co.th

Contact person:

Mrs. Oranuch Inprom

Finance Manager

E-mail: info@gwadvance.co.th

Phone: +66 8 77177910

Mr. Nitinan Pengboot

Business development

E-mail: nitinan@gwadvance.co.th

Phone: +66 9 14466455

Mr. Panat Chouyniam

Project Manager

E-mail: panat@gwadvance.co.th

Phone: +66 87 3294977

Mr. Komkrit Saneechai

Service Manager

E-mail: Komkrit@gwadvance.co.th

Phone: +66 (0)89-855-9982

Mr. Narongrit Tanwattanaseree

Project Manager

E-mail: Narongrit@gwadvance.co.th

Phone: +66-92-259-6141

Mr. Santinai Wattanasri

Project Engineer

E-mail: santinai@gwadvance.co.th

Phone: +66 9 7119-5735

Mr. Phongsakorn Phornsiriyada

Project Engineer

E-mail: phongsakorn@gwadvance.co.th

Phone: +66 (0) 91 7390 341

Mr. Suphachai Nonthasin

Project Engineer

E-mail: suphachai@gwadvance.co.th

Phone: +66 63-737-7109

Mr. Wasin Wachirapanee

Service Engineer

E-mail: wasin@gwadvance.co.th

Miss Maneerat Maion

Admin / Sale Engineering

E-mail: maneerat@gwadvance.co.th

Phone: +66 84 585 1765

Miss Alisa Chanratsami

Admin/Project Coordinator

E-mail: admin@gwadvance.co.th

Phone: +66 9 10193797

Mr. Sarunyaphat Santawong

Sales Engineer

E-mail: sarunyaphat@gwadvance.co.th

Phone: +66 8 76502192

Miss Kunlanat Ninprakhon

Admin / Accounting

E-mail: account@gwadvance.co.th

Phone: +66 64 2044920

Mr. Naphat Inprom

Technical Engineer

E-mail: Sales@gwadvance.co.th

Products & Services

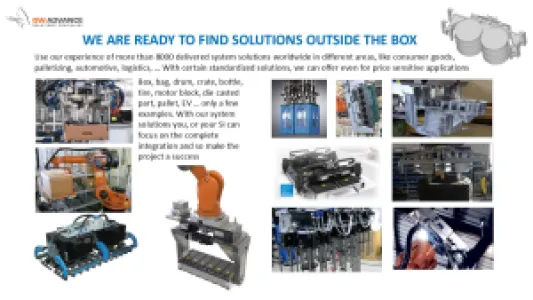

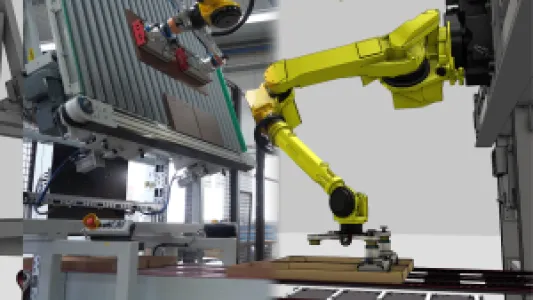

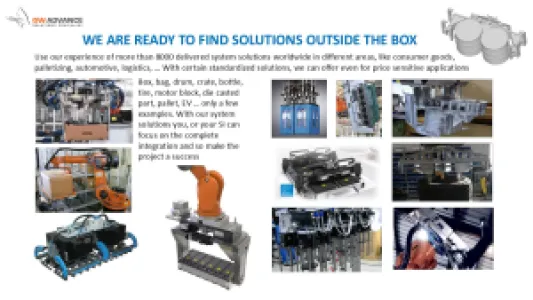

We are robotic automation integrators. To provide machine and equipment for industrial automation to our customers with quality products and solutions as well as collaboration with our customers and suppliers to deliver the technical expertise for productivity improvement.

We are authorized distributor of world class such as KUKA,Dürr ,FRANKA ROBOTICS, SIEMENS ,ZIMMER ,FESTO, OrangeAPPs, Visual Components

KUKA

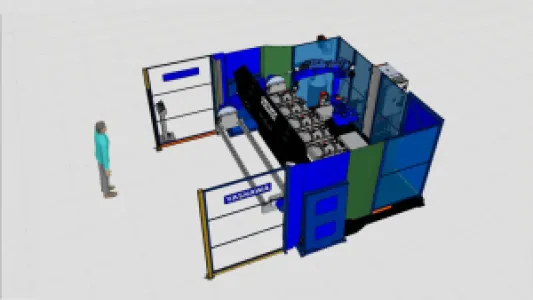

KUKA offers a comprehensive range of industrial robots, catering to diverse applications with precision, flexibility and efficiency.

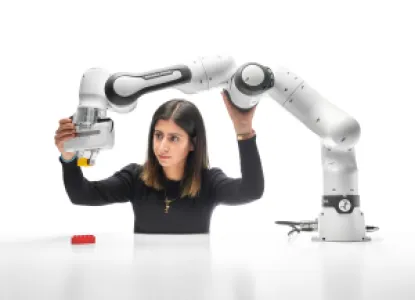

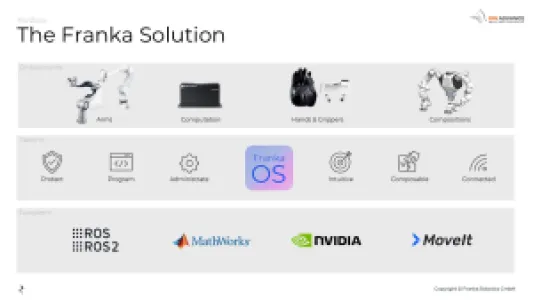

FRANKA ROBOTICS

FRANKA RESEARCH 3

Franka Research 3 is the reference world-class, force-sensitive robot system tailored for robotics and AI. It empowers researchers with easy-to-use robot features as well as with low-level access to robot’s control and learning capabilities.

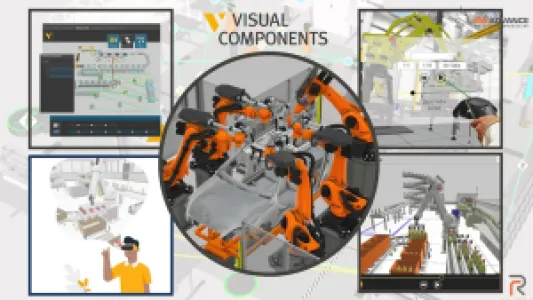

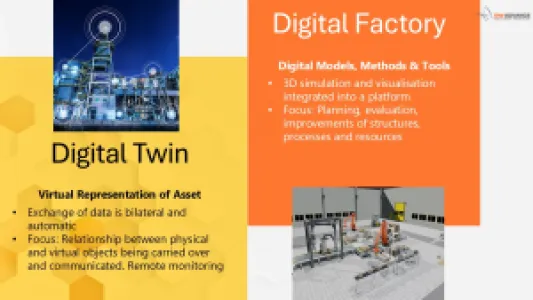

Visual Components

Visual Components is a developer of 3D simulation software for manufacturing. Visual Components software is used for applications including layout planning, production simulation, off-line programming and PLC verification.

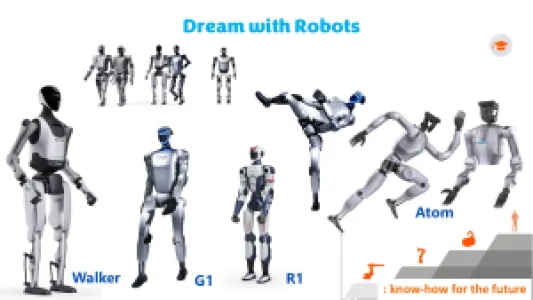

DALLAS ROBOTER

Dallas Roboter Inc is an upcoming Robotics Start-up HQ in Dallas, Texas

+ Engineering Center in Cyberjaya, Malaysia

+ Sales & Operation throughout Asia & Oceania

ZIMMER / FESTO GRIPPER

Zimmer Gripper: Efficient automation solutions

Success through innovation: Your partner for customized automation, components and systems for future-oriented solutions.

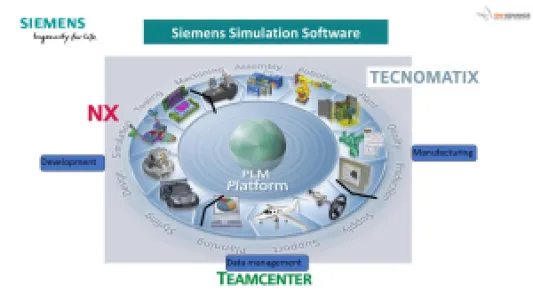

Siemens PLM

engineering software

Design, manufacturing and lifecycle management

Use our comprehensive portfolio of engineering software, hardware and services to design products, realize their potential and optimize their performance – before you even build anything.

Customer Care

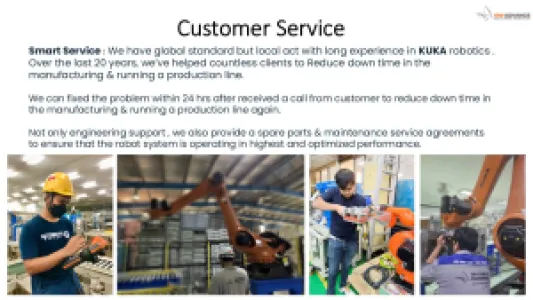

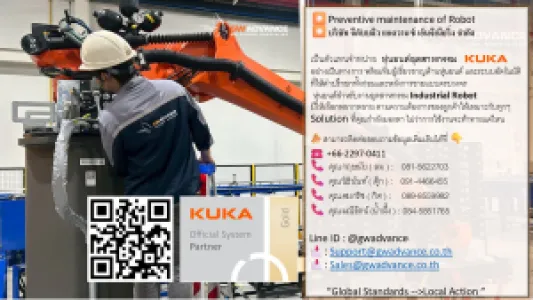

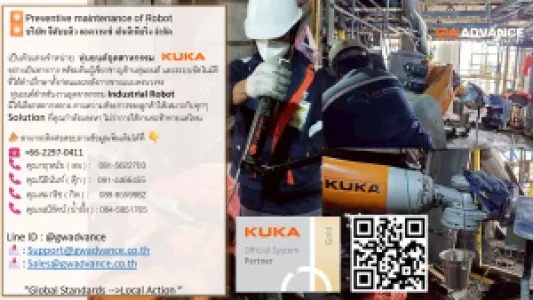

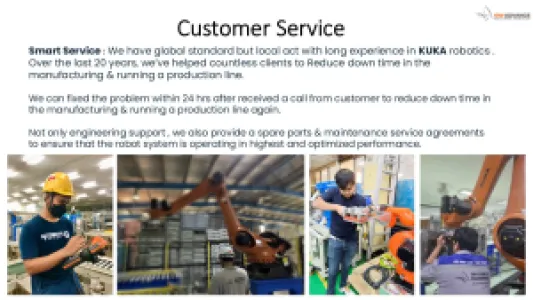

Customer Service

Smart Service : We have global standard but local act with long experience in KUKA robotics .

Over the last 20 years, we’ve helped countless clients to Reduce down time in the manufacturing & running a production line.

We can fixed the problem within 24 hrs after received a call from customer to reduce down time in the manufacturing & running a production line again.

Not only engineering support , we also provide a spare parts & maintenance service agreements to ensure that the robot system is operating in highest and optimized performance.

-thumb.webp)

-thumb.webp)

-thumb.webp)

-thumb.webp)

_Franka_300dip.png)

_Zimmer_300dip.png)

300dip.png)